1. Microalgae and its metabolites

1.6 Low value products: biofuel, biofertilizer and other low-value alternatives.

Questions and exercises.

-

•Did you hear the term “biorefinery”? What do you think a microalgal biorefinery would be like?

LITERATURE

Ramos-Suarez J, Carreras N (2014) Chemical Engineering Journal 242, 90-93.

Romero Garcia JM, Acien-Fernandez FG and Fernandez-Sevilla JM (2012) Bioresource Technology 112, 164.170

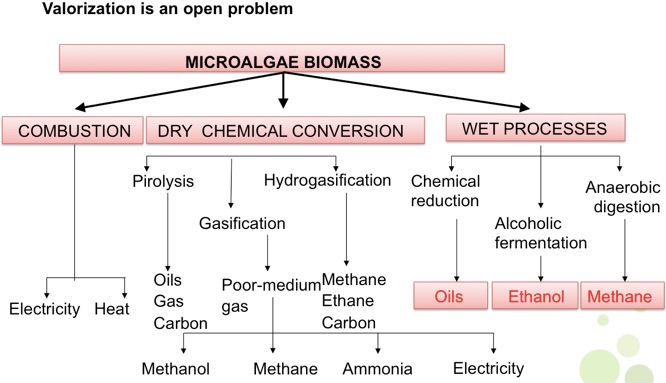

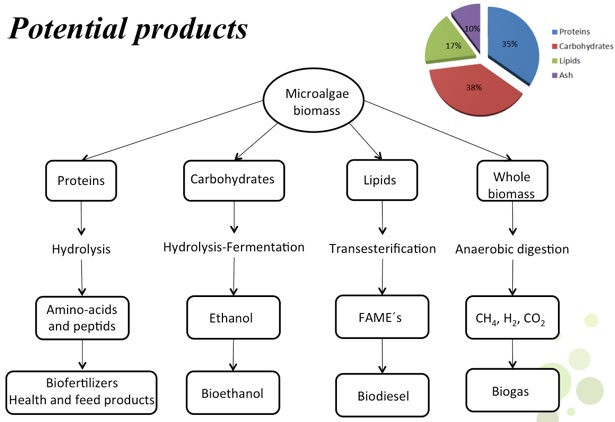

When discussing what products can be obtained from microalgal biomass, it is important to distinguish between high and low value products since the processing strategies are very different.

-

• For high-value products, such as pigments, antioxidants, certain fats and fatty acids and others, it is important a high purity, quality and integrity. Culturing and processing costs are secondary. By-products can be disposed off as these are produced in low volumes.

-

• Low-value products are produced in a large scale and tend to become commoditized. Production and processing costs are critical and is is not possible to produce significant proportion of by-products. For instance, it is not possible to produce biodiesel from microalgae and dispose off the large amounts of biomass and carbohydrates that make up the rest of the biomass.

Below are shown high-volume, low-value products that can be obtained from microalgal biomass.

Whatever the processing option it is important to bear in mind that the biomass must be used as completely as possible. Let’s see some of the processes suggested above.

Biofertilizers

The protein fraction in the microalgal biomass can be hydrolized to render a solution of aminoacids that can be used as biofertilizers. This process is important as it helps to recover the nitrogen used to generate the microalgal biomass.

Recovering the nitrogen it is important as ir is a significant part of the culturing costs.

Additionally, if waste water (such as sewage) is used as culture medium, microalgae offer a unique processing alternative to recover the N that has been used to grow the crops that feed animals and humans. In the end, this results in a decrease in the needs of fertilizers which are costly to produce in terms of energy and money.

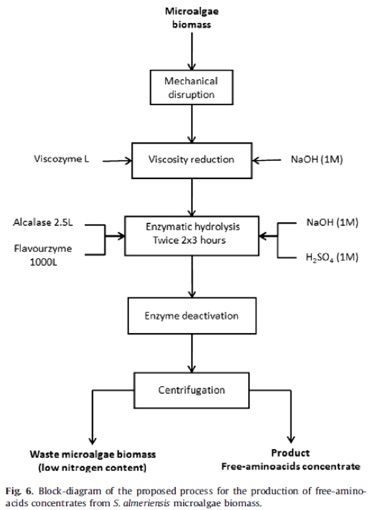

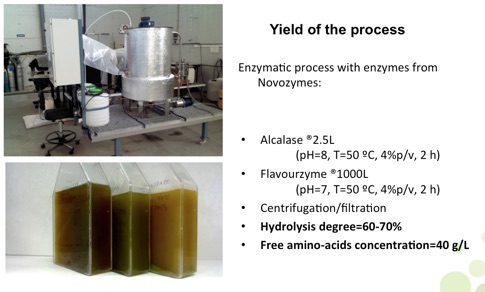

On the right is shown an alternative to produce biofertilizers from microalgal biomass as proposed by Romero et al (2012).

This process uses enzymes that promote extensive hydrolization of the proteins under mild conditions, which is advantageous as the rest of the components are preserved and can be user at a later stage.

Some details of the process are shown below.

Biodiesel

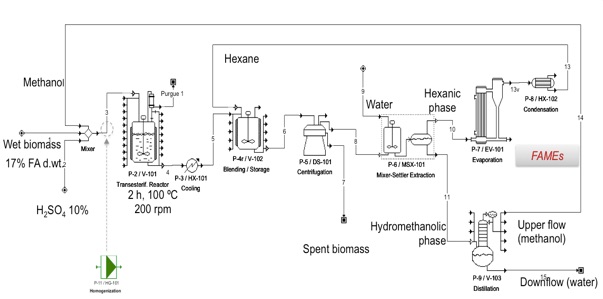

Biodiesel is a mixture of methyl or ethyl esters of adequate fatty acids obtained by transesterification of fats.

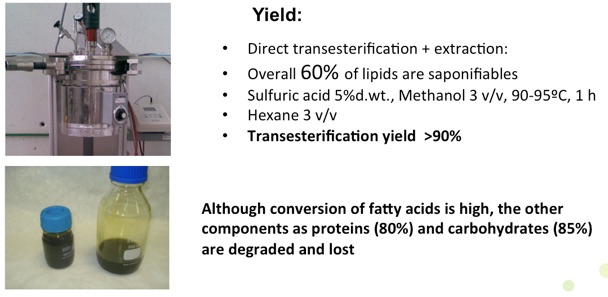

Biodiesel can be obtained from the fatty (saponifiable) part of microalgal biomass. An example process is shown below:

Which uses sulphuric acids as catalyst. The process is efficient (90%) but also has some drawbacks as shown below:

Bioethanol

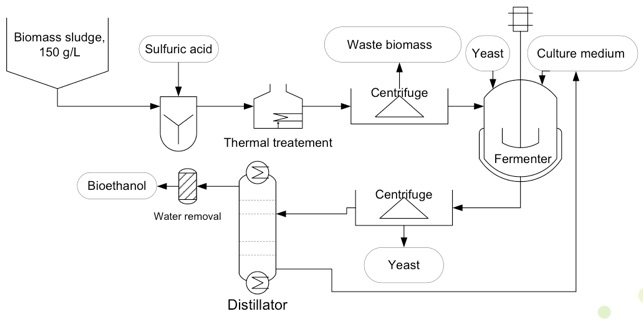

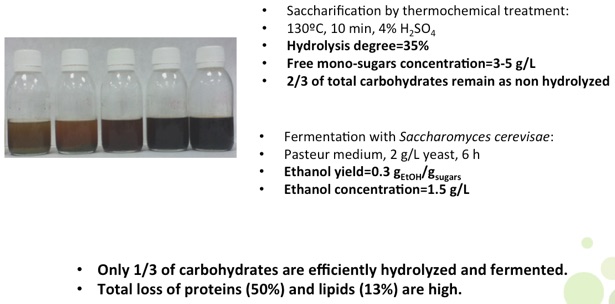

Bioethanol can be obtained from the carbohydrate fraction found in the biomass. A significant proportion of these are structural carbohydrates which are very difficoult to breack down and thus require harsh conditions as shown below:

The yield of the process is low and, what is worse, the extreme T and pH conditions denaturalize and destroy the other components in significant proportions.

Biogas

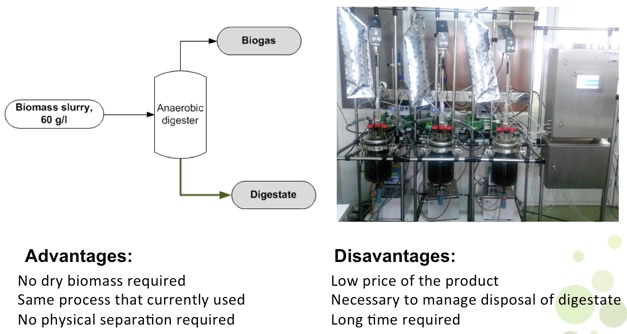

Biogas production is an unespecific but flexible process that uses a consortium of anaerobic bacteria to break down the microalgal biomass giving rise to a gas that contains methane in a large proportion (as well as CO2 and other compounds)

Digestors need very long residence times (months) and produce a significant amount of digestate that needs to be disposed off although it ca be used as fertilizer or, at least, a a soil stabilizer.

INTEGRATED PROCESSING

None of the process shown above can use all the biomass or at least a large part of all the three main components of the biomass, proteins, lipids and carbohydrates.

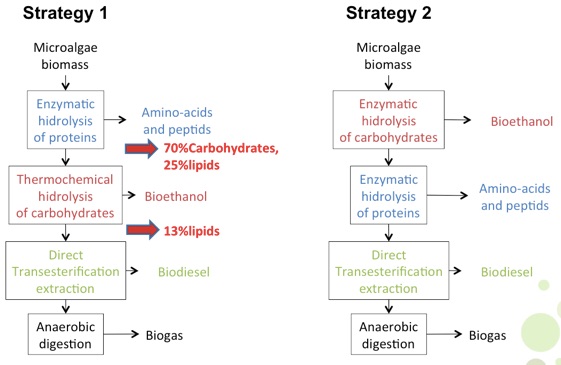

Integrated strategies are combinations of the processes mentioned above. These strategies aim for a use of the biomass as complete as possible with the lover processing costs and the highest added value.

Two rather straightforward integrated strategies are shown below.

By no means those are the only processing options possible. In point of fact microalgal biomass is still not very well known as an industrial feedstock and many processing options may be still to come. Microalgal valorization is, thus, an open problem.